Common Questions Electronic Engineers Ask When Selecting LiPo Batteries

When electronic engineers evaluate LiPo batteries for new device designs, they encounter numerous technical, safety, and practical considerations that directly impact product performance, user safety, and commercial viability. This guide addresses common questions and concerns about LiPo battery selection and concerns during LiPo battery selection.

1. Technical Specifications and Performance Parameters

1.1 Voltage & Cell Configuration Questions

Engineers consistently ask about nominal voltage requirements and cell configurations. LiPo battery has a nominal voltage of 3.7V, 3.8V&3.85V per cell, with a fully charged voltage of 4.2V, 4.3V&4.4V and a discharge cutoff voltage typically around 2.80V to 3.0V. Multi-cell configurations are designated as 1S (3.7V), 2S (7.4V), 3S (11.1V), 4S (14.8V), and so forth, allowing engineers to match their device's voltage requirements. The usable voltage range is critical for circuit design, as LiPo batteries operate between 3.2V and 4.2V per cell during everyday use. Any voltage below 3.2V may cause permanent damage, while exceeding 4.2V significantly increases fire risk.

The usable voltage range is critical for circuit design, as LiPo batteries operate between 3.2V and 4.2V per cell during everyday use. Any voltage below 3.2V may cause permanent damage, while exceeding 4.2V significantly increases fire risk.

1.2 Capacity & Runtime Calculations

Battery capacity selection represents one of the most common engineering challenges. Capacity, measured in milliampere-hours (mAh) or ampere-hours (Ah), determines device runtime. Engineers must balance capacity requirements with size and weight constraints, often asking how to calculate optimal capacity for their specific current draw profiles.

The fundamental relationship is: Runtime = Battery Capacity ÷ Load Current. Real-world calculations must consider temperature effects, discharge rates, and aging. Engineers typically use a 0.8 derating factor for practical applications to accommodate environmental conditions and battery aging.

1.3 C-Rating & Discharge Rate Considerations

C-rating questions dominate technical discussions, as this parameter determines the maximum safe discharge current. The C-rating represents how quickly a battery can safely deliver its stored energy, with 1C meaning it can discharge its full capacity in one hour.

For example, a 1000mAh battery with a 25C rating can safely deliver 25 amps continuously (1.0Ah × 25C = 25A). Engineers must ensure their device's current requirements don't exceed the battery's continuous C-rating to prevent voltage sag, overheating, or safety hazards.

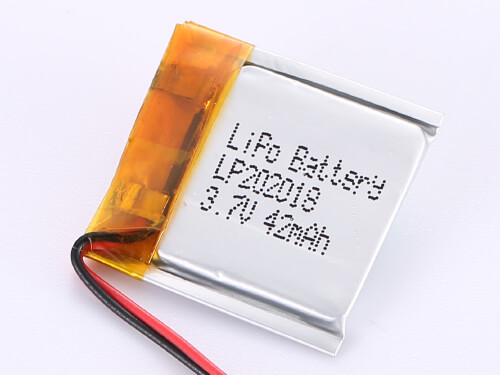

Ultra Thin LiPo Battery 0.4 - 3.0mm

Standard LiPo Battery by Capacity

2. Safety & Risk Management Concerns

2.1 LiPo Battery Swelling & Mechanical Design

LiPo battery swelling represents a critical safety concern that engineers must address in their mechanical designs. Swelling occurs due to gas buildup inside the battery cells, typically caused by overcharging, over-discharging, high temperatures, or physical damage.

Engineers commonly ask about design allowances for battery expansion. Due to chemical degradation, LiPo cells can grow up to 10% thicker over their lifetime. Proper mechanical design must accommodate this expansion while preventing dangerous pressure buildup.

2.2 Temperature Considerations & Environmental Limits

Operating temperature ranges generate numerous engineering questions. Standard LiPo batteries typically operate between -20°C to 60°C for discharge and 0°C to 45°C for charging. However, performance degrades significantly outside optimal ranges of 15°C to 35°C.

Engineers must consider that cold temperatures reduce capacity and increase internal resistance, while high temperatures accelerate aging and increase safety risks. For extreme environments, specialized low-temperature or high-temperature LiPo formulations are available.

2.3 Battery Management System Integration

BMS requirements represent complex engineering decisions involving safety, performance, and cost trade-offs. Engineers ask about protection circuit features including overvoltage protection, undervoltage protection, overcurrent protection, short-circuit protection, and temperature monitoring (thermistor or NTC).

Modern BMS designs integrate voltage monitoring, current sensing, temperature measurement, and cell balancing functions. Active balancing becomes essential for multi-cell configurations to maximize battery life and safety.

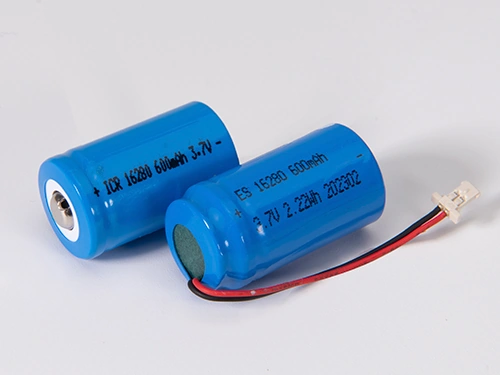

Cylindrical Li-ion Battery

Round LiPo Battery

3. Physical Design & Form Factor Questions

3.1 LiPo Battery Size & Weight Constraints

Physical integration challenges frequently arise as engineers balance capacity requirements with device size limitations. LiPo batteries offer significant advantages in form factor flexibility, as they can be manufactured in virtually any shape using flexible aluminum-laminated packaging.

3.2 Connector Selection & Integration

Connector compatibility questions span electrical, mechanical, and safety considerations. Engineers must select connectors based on current capacity, physical size constraints, and industry standards. Common connector types include JST SHR(1.0mm), JST PHR(2.0mm), JST ACH(1.2mm), Molex 51021(1.25mm), Molex 78172(1.2mm) and Hirose connectors. The choice depends on current requirements, space constraints, and standardization preferences.

LiHv Battery 3.8V 3.85V 3.90V

18650 Battery

4. Certification & Regulatory Compliance

4.1 Safety Standards & Certifications

Certification requirements vary by market and application, with engineers asking about UL2054, UL1642, CE, CB, EU, UN38.3, IEC62133, MSDS, FCC, RoHS, REACH, CCC, KC, BIS, and other standards. UL2054 certification is often required for US markets for lipo battery, while UL1642 covers individual cells. For European markets, CB & CE certification is needed for lipo battery. A UKCA certificate is required for the lipo battery for the UK market since the UK left the European Union. Korean market requests the KC certificate, and Indian market requires a BIS certificate for the lipo battery.

4. 2 Transportation regulations under UN38.3 & MSDS are mandatory for shipping LiPo batteries, requiring specific testing for altitude, thermal, vibration, shock, external short circuit, impact, overcharge, and forced discharge conditions.

5. Cost & Supply Chain Considerations

5.1 Economic Factors and Pricing

Cost optimization questions focus on balancing performance requirements with budget constraints. LiPo battery costs depend on capacity, chemistry, safety features, and production volumes. Engineers must consider total cost of ownership, including replacement frequency and warranty implications.

Supply chain resilience has become increasingly important, with engineers asking about sourcing strategies, lead times, and supplier qualification. The global battery supply chain faces challenges from raw material availability, geopolitical factors, and manufacturing capacity constraints.

5.2 Sourcing and Supplier Selection

Supplier evaluation involves technical capability assessment, quality certifications, production capacity, and long-term viability. Engineers must balance cost considerations with quality requirements, often requiring suppliers to demonstrate compliance with automotive or aerospace quality standards.

6. Lifecycle and Reliability Questions

6.1 LiPo Battery Aging & Degradation

The Cycle life optimization of lipo battery represents a significant engineering concern, as LiPo batteries typically provide 500-1000+ cycles depending on usage patterns. Engineers ask about strategies to maximize battery life through depth of discharge control, charging algorithms, and thermal management.

Capacity retention over time depends on temperature, state of charge during storage, and cycling patterns. Maintaining batteries at 40-80% state of charge during operation can significantly extend cycle life compared to complete charge/discharge cycles.

6.2 Testing and Validation Requirements

Performance testing protocols must validate capacity, cycle life, safety, and environmental performance. Engineers require standardized testing procedures to compare lipo battery options and validate design decisions.

Accelerated aging tests help predict long-term performance, though correlating accelerated test results to real-world performance remains challenging.

7.2 Power Management Integration

System integration challenges include voltage regulation, power sequencing, and fault handling. Engineers must design robust power management systems that handle battery voltage variations, implement safe shutdown procedures, and provide accurate state-of-charge estimation. Fuel gauging accuracy depends on sophisticated algorithms that account for temperature, aging, and discharge history. Modern implementations use microcontrollers with integrated analog front-ends to provide precise battery monitoring.

These comprehensive considerations demonstrate that LiPo battery selection involves complex trade-offs between performance, safety, cost, and regulatory compliance. Successful implementation requires a thorough understanding of battery technology fundamentals and specific application requirements. Engineers must approach battery selection as a system-level design challenge that impacts every aspect of device performance and user safety.